Forklifts keep Toronto’s warehouses, construction sites, and distribution centers moving. But they won’t stay reliable without care. A worn-out tire, a loose chain, a leaking cylinder, these issues don’t just pop up out of nowhere. They develop slowly and silently. And if you’re not paying attention, one day your forklift just doesn’t start. Or worse, it starts, and then fails mid-operation. Either way, it costs you time, safety, and a whole lot of money.

That’s where maintenance comes in. Preventive maintenance isn’t about doing more work; it’s about avoiding more problems. Forklift maintenance is a fundamental part of keeping your business running. And whether you manage a single forklift or an entire fleet, a solid maintenance routine helps you avoid breakdowns, keep your workers safe, and save serious money in the long run.

At Forklift Toronto, we offer much more than just maintenance; we provide reliability, confidence, and continuity. Our forklift maintenance services are built to prevent the problems you don’t see yet, and to handle the ones you can’t afford to ignore, minimizing the risk of costly repairs. With the right routine, your forklifts last longer, run smoother, and keep your team safe. This guide breaks it all down. Not with fluff or vague tips, just clear steps, useful lists, and straight talk.

Why Forklift Maintenance Isn’t Optional

Forklifts aren’t just another piece of equipment you can toss aside when they get a little worn out. They’re serious investments, big-ticket machines that often come with price tags running well into tens of thousands of dollars, whether you’re talking about electric models, gas-powered, or diesel-fueled beasts. Think about it: these aren’t tools you buy every year. They’re meant to be the workhorses of your operation for many years, moving heavy loads day in and day out. So treating them like disposable or replaceable items is not just careless, it’s throwing money down the drain.

But the financial side, while important, only scratches the surface. The bigger concern is safety, plain and simple. A forklift that isn’t maintained properly can quickly turn from a reliable helper into a serious hazard on your floor or site. Picture this: brakes that don’t respond when they should, hydraulic systems that seize up, forks that unexpectedly drop their load. It’s not just inconvenient, it’s dangerous. People can get injured, sometimes very badly. And beyond the human cost, accidents can mean costly shutdowns, insurance claims, and damage to your company’s reputation.

On top of that, it’s not just common sense or best practice, it’s the law. Here in Ontario, workplace safety regulations are clear and strict. Regular inspections and maintenance aren’t optional checkboxes; they’re legal requirements. Neglecting your maintenance duties doesn’t just risk equipment failure, it can lead to hefty fines, penalties, or even legal action if someone gets hurt due to negligence.

This is why having a solid, well-planned forklift maintenance program is essential. It’s your best defense against surprises, accidents, and unexpected costs. A robust maintenance plan helps you:

- Catch small issues before they become expensive disasters

- Keep your forklift operators and everyone around them safe and sound by adhering to safety standards.

- Stay compliant with provincial health and safety laws without stress

- Stretch the useful life of your forklifts, getting more bang for your buck

- Avoid costly and frustrating delays caused by breakdowns

- Keep your operations humming smoothly with maximum uptime

- Protect the considerable investment you’ve made in your equipment

Here, at Forklift Toronto, we offer all sorts of forklift services including forklift sale and forklift rental in Toronto as well. You can contact us any time to speak with one of our technicians to help you with your material handling needs.

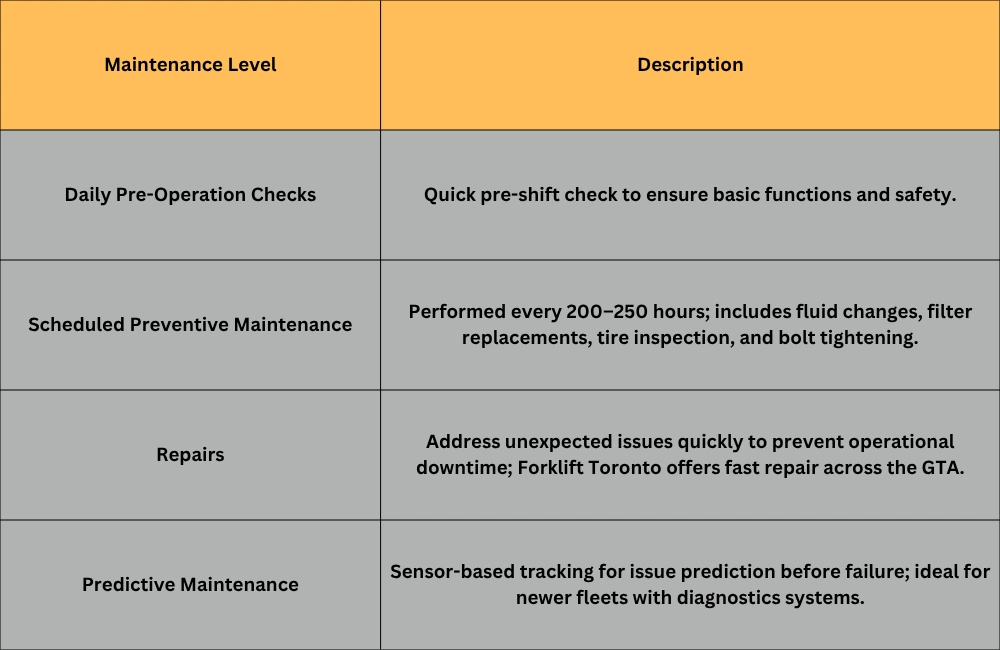

The Four Levels of Forklift Maintenance

1.Daily Pre-Operation Checks

This is your first line of defense. It’s a quick walkthrough and test to make sure everything works before you even start a shift.

2.Scheduled Preventive Maintenance

Usually performed every 200–250 hours of operation. This involves changing fluids, replacing filters, inspecting tires, and tightening bolts.

3.Repairs

Even with perfect care, things still break down. The goal is to catch them fast and fix them before they turn into downtime disasters, ensuring smooth operation. And if your forklift ever breaks down in the middle of an operation, here at Forklift Toronto, we specialize in fast, dependable, and precision-tuned forklift repair services across the GTA. You can count on us, always.

4.Predictive Maintenance

This is more common in newer fleets. It involves using sensors, onboard diagnostics, and tracking data to detect issues before they become failures.

Daily Forklift Maintenance Checklist

The daily inspection should only take about 5–10 minutes, but it’s crucial. Here’s what your operators should check before turning the key:

Visual Checks

- Leaks: Check under the machine for oil, coolant, fuel, or hydraulic fluid.

- Tires: Look for deep cuts, missing chunks, or embedded debris.

- Forks: Ensure they’re straight, not cracked or bent, and have equal height.

- Mast & Chains: Look for rust, missing pins, or loose connections.

- Overhead Guard: Should be secure and undamaged.

- Hydraulic Hoses: Check for swelling, cracks, or leaks.

- Labeling: Make sure the load rating plate is readable and up to date.

Operational Checks

- Horn, headlights, and warning lights

- Brake responsiveness and parking brake hold

- Steering: smooth and not loose

- Seatbelt locks securely

- All controls: lift, lower, tilt, side shift

- Gauges and display lights: check for any error messages

Weekly Forklift Maintenance Tasks

Each week, go deeper with a mechanical inspection. These are tasks a trained operator or maintenance tech should handle:

- Clean the battery top (electric forklifts) to prevent corrosion and maintain proper electrolyte levels

- Check water levels in the battery and top off with distilled water

- Inspect all drive belts for signs of wear or cracking

- Clean the radiator fins to prevent overheating (internal combustion models)

- Inspect exhaust systems and mufflers for signs of leaks

- Lubricate mast channels and chain rollers

- Verify load backrest and seat mounting bolts are tight

Monthly Forklift Service Checklist

Monthly inspections should be carried out by trained mechanics to adhere to maintenance schedule guidelines. They allow you to catch wear-and-tear before it becomes a hazard, enhancing overall productivity and extending the lifespan of your equipment.

- Change oil and oil filters (gas/diesel forklifts)

- Replace or clean air filters

- Lubricate all mast fittings, pivot points, and wheel bearings

- Inspect brake pads and adjust if necessary

- Check the condition and tension of the drive chain

- Inspect transmission fluid and top off if needed

- Test electrical systems: horn, alarms, and lights

- Examine tilt and lift cylinders for leaks

- Test inching pedal and transmission engagement

Quarterly and Semi-Annual Maintenance

Every 3–6 months, schedule a more thorough evaluation of your fleet:

- Flush and replace hydraulic fluid

- Replace fuel filters (for gas and diesel forklifts)

- Perform a battery load test

- Inspect hydraulic cylinders for scoring and seal integrity

- Check mast rollers for roundness and wear

- Clean and lubricate carriage bearings and roller guides

- Inspect differential fluid and change if needed

- Perform load-handling test under weight

- Examine wiring and connectors for signs of wear or heat damage to ensure your forklift remains in working order.

Annual Forklift Maintenance Checklist

This is your forklift’s version of a full physical exam. You’ll want to go through everything, thoroughly:

- Full engine tune-up: spark plugs, fuel lines, filters

- Coolant flush and radiator pressure test

- Brake system inspection and flush

- Transmission flush and torque converter inspection

- Emissions testing (if required by your municipality)

- Fork wear inspection using calipers (replace if worn by 10% or more)

- Structural inspection: frame, counterweight, carriage, mast

- Steering and hydraulic system pressure tests

- Comprehensive battery inspection and terminal cleaning (electric models)

- Review of service records for recurring issues or trends

Electric vs. Internal Combustion Forklift Maintenance

Electric forklifts and gas/diesel forklifts each come with their own care routines.

Electric Forklifts

- Keep battery water levels filled (use distilled water only)

- Equalize the battery charge weekly

- Clean battery terminals with baking soda solution

- Avoid overcharging or undercharging

- Monitor temperature and avoid extreme heat during charge cycles

- Ensure the charger matches the battery spec to maintain the proper electrolyte levels and extend the lifespan of your battery.

Gas/Diesel Forklifts

- Check and replace spark plugs and ignition wires

- Clean or replace air and fuel filters

- Inspect exhaust system for leaks or carbon buildup

- Maintain proper oil levels and change it at scheduled intervals

- Watch for carbon buildup in valves and combustion chambers

No matter what kind of warehouse you work in or what forklift model you use, it’s crucial to know the 10 Rules for Forklift Safety for a safe and peaceful operation.

Forklift Tire Maintenance

Tires are one of the most overlooked parts of the machine, but they’re a huge safety factor.

What to Watch For

- Flat spots from parking too long

- Chunking (rubber breaking off)

- Tread wear indicators

- Heat cracking (common in outdoor use)

- Uneven wear (may indicate steering issues)

When to Replace

- Tire height is 2″ less than original

- 60% or more of tread is gone

- Tire has splits or sidewall damage

- Increased vibration during operation

Air vs. Solid Tires

- Pneumatic tires must be checked for proper pressure weekly

- Solid tires need height measurements, not air pressure

- Indoor use = solid cushion tires

- Outdoor/rough terrain = air-filled pneumatic tires

Lubrication and Greasing Points

Friction is your forklift’s enemy. Regular greasing keeps moving parts operating smoothly. Grease at least monthly:

- Mast rollers

- Tilt cylinder pins

- Steer axle pivots

- Lift chains and sheaves

- Brake pedal joints

- Control lever pivots

Always use the grease recommended in the manufacturer’s manual. Over-greasing can be just as damaging as under-greasing.

Maintenance Records: Why They Matter

Keeping detailed records isn’t just smart, it’s necessary. Here’s why:

- Legal Compliance: Inspectors will ask for logs.

- Planning: You’ll be able to spot repeat problems and schedule parts in advance.

- Budgeting: Helps you estimate monthly/yearly service costs.

- Resale: Shows the next owner the machine was well cared for.

- Warranty Claims: Manufacturers may void warranties if there’s no record of maintenance.

Use digital fleet management tools or simple spreadsheets. Either way, log everything: date, hours, parts used, technician’s name, and notes on maintenance needs and issues.

In-House vs. Outsourced Maintenance

There’s no one-size-fits-all answer. It depends on the size of your fleet, your staffing, and your operating hours.

In-House

In-house forklift maintenance? That’s when your own team, meaning your mechanics, your tools, and your space, handle all the repairs and upkeep. Everything stays under your roof, on your schedule, your terms. Full control, full responsibility.

Pros:

- Quicker response

- Full control over scheduling and inventory

- Potential cost savings for large fleets

Cons:

- Need skilled technicians on payroll

- Requires parts stock and tools

- Need to manage documentation internally

Outsourced

Outsourced forklift maintenance? You call in the pros. A third-party company rolls in, diagnoses, fixes, maintains off-site or on-site. You focus on business, they focus on forklifts. Less control, but way less hassle.

Pros:

- Certified, specialized technicians

- Compliance-ready reporting

- Scalable service contracts

Cons:

- Per-visit cost can be higher

- May not respond as fast for minor issues

Many companies use a mix: internal checks and cleaning, with quarterly or annual outsourced service.

Forklift Maintenance Costs

Forklift maintenance costs? Honestly, it depends. That’s not a dodge, it’s just the truth. Some machines barely need anything aside from routine checks and fluid top-ups. Others, especially if they’re older or working long shifts in rough conditions, can chew through parts and rack up bills fast. We’ve seen basic service calls cost under a couple hundred bucks. We’ve also seen full overhauls that go well into the thousands. It’s not predictable, and that’s exactly why ballpark figures don’t help much.

There are a ton of factors at play: What kind of forklift are you running? How often is it in use? Indoors or outdoors? Electric, diesel, propane? Is it lifting heavy pallets on uneven ground or just moving light loads in a clean warehouse? All of that affects what maintenance will look like, for your machine, not just “a forklift.”

So instead of guessing or Googling half-useful numbers, just reach out to discuss your maintenance needs. Call us, email us, or come by. At Forklift Toronto, we’ll take a real look at your setup and tell you what you’re likely to spend, not some generic average, but an honest number based on your equipment. No upselling. No fluff. Just the truth, so you can plan smart.

And if you ever need any kind of forklifts for your operation, we have almost every forklift model from major brands including Toyota forklifts for sale, or Yale forklifts for sale in Toronto.

How Maintenance Reduces Overall Business Costs

Let’s be practical: yes, maintenance has a cost. But it’s a fraction of what breakdowns cost, especially when considering the impact on productivity.

Imagine this:

- Forklift breaks down during peak hours: lost time = lost revenue

- Waiting on a part from out-of-province = delays

- Emergency repair crew = premium labor rates

- Damaged goods from a hydraulic failure = write-offs

- Worker injured from failed brakes = legal + moral cost

A solid maintenance plan turns these risks into rare events. It lets you plan instead of react.

When it comes to forklift parts, we supply parts for all brands, OEM or aftermarket. You can check our inventory to see if we currently have the part that you need for your operation, including Crown forklift parts or Raymond forklift parts for sale.

Final Word

Forklifts are machines, sure, that’s obvious. They’re made of steel, hydraulics, grease, and circuits. But to say they’re “just machines” doesn’t quite capture how central they are to your material handling operations. Because in the day-to-day pulse of your warehouse or yard, forklifts aren’t just pieces of equipment. They’re practically teammates. They lift what no human can. They ferry goods across concrete floors, in and out of trailers, up and down warehouse racks, tirelessly repeating the same demanding motions, hour after hour, shift after shift.

When a forklift’s running smoothly, it’s invisible. It just…works. Your team gets orders out the door on time, production lines keep moving, schedules stay on track. But when a forklift goes down, suddenly it’s not invisible at all. It’s the only thing anyone talks about. Workers stand around waiting. Orders back up. Tempers flare. Costs creep higher by the minute.

So keeping forklifts in top shape isn’t just about ticking boxes on a compliance sheet. It’s about safety, so no one’s put in harm’s way. It’s about efficiency, because wasted time is money slipping right through your fingers. And it’s about peace of mind so you’re not jolted awake at 2 a.m. by the thought of a forklift out of service during peak season.

Whether you’ve got a single trusty lift truck or a buzzing fleet of fifty machines crisscrossing your facility, one truth doesn’t change: maintenance matters. A solid, consistent maintenance plan is one of the best business decisions you’ll ever make. It’s your insurance policy against chaos. It’s your strategy for protecting the significant investment you’ve poured into these machines. And honestly, it’s one of the simplest ways to keep your business rolling without unwanted surprises.

So don’t leave it to chance. Print these checklists. Post it in the break room. Train your team until it’s second nature. Make forklift care as routine as checking your morning emails or locking the doors at closing time. Because when your forklifts run right, your whole business runs right, and your bottom line breathes a sigh of relief.

And if the day ever comes when you’re staring at a hydraulic leak you can’t identify, or you’ve got a forklift refusing to start on a freezing Toronto morning, don’t sweat it alone. Forklift Toronto is right here, ready to jump in and get you back on track. Let’s keep your forklifts working as hard as you do.